MAN achieves full in-house battery production in 2025, marking a milestone in its European electric-bus manufacturing strategy.

MAN Now Capable to Produce a Fully Integrated Electric Bus In-House

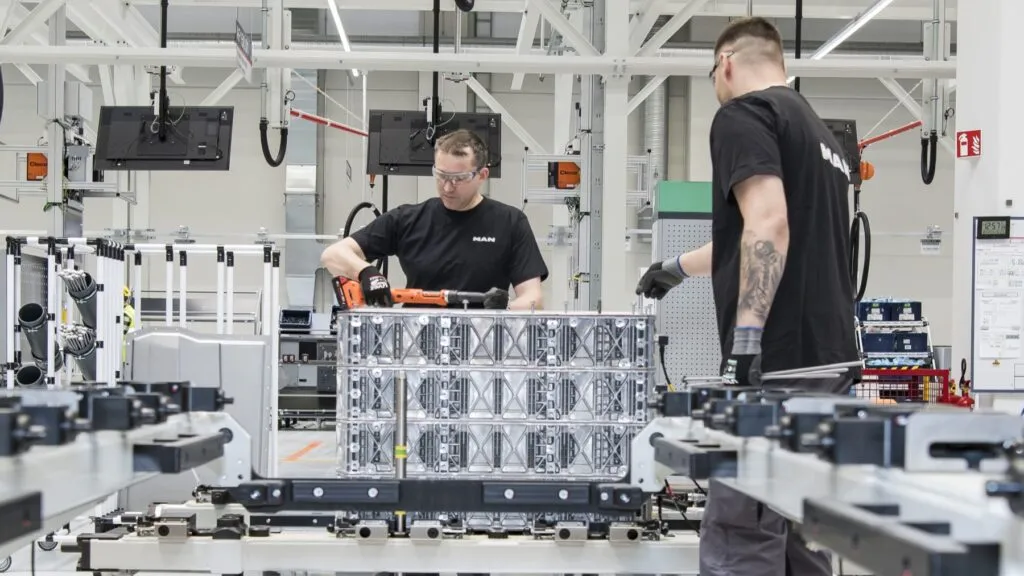

MAN Truck & Bus announced that, beginning in 2025, all of the Lion’s City E buses will be powered by the company’s own next-generation lithium-ion batteries, produced at its Nuremberg plant in Germany. This shift marks a milestone for MAN, by integrating one of the most critical components of e-mobility into its own manufacturing infrastructure.

The Nuremberg facility will have an initial capacity of up to 50,000 battery packs per annum. Each unit represents MAN‘s latest lithium-nickel-manganese-cobalt (NMC) cell technology, specially engineered for commercial vehicles. Lighter, more powerful, and more energy-dense than their predecessors, these battery packs offer increased range, improved performance, and, thereby, lower total operating costs (TOC) for operators.

By bringing battery production in-house, MAN puts itself in a special position as one of the few European manufacturers capable of producing a fully integrated electric bus, from drivetrain to energy storage, in-house.

“By using our own MAN batteries from 2025 onwards, all important components of our eBuses will now come from within the Group,” explained Robert Katzer, Managing Director of MAN Truck & Bus. “This enables us to guarantee the highest quality and continuous further development of the components, an important basis for achieving our goal. By 2030, we want to deliver up to 90 per cent of our buses in Europe with battery drive.”

The new MAN BatteryPack is based on a modular architecture that allows operators to choose configurations according to their needs. For the 12-metre Lion’s City E, for instance, four or five packs can be installed, offering 356 or 445 kWh of energy capacity. The 18-metre coach, meanwhile, can carry six to seven packs, supplying 534 or 623 kWh respectively. Each pack now has a higher energy density, which means fewer units are needed in each bus, thus freeing up space for passengers and reducing total vehicle weight.

The battery’s safety has also been improved with an advanced NMC chemistry, a sophisticated Battery Management System to monitor cell health and temperature, and thermal regulation that ensures the cells remain within optimal operating conditions.

Another important aspect is sustainability, something that MAN is taking seriously. The Nuremberg plant follows a circular manufacturing approach, designed for resource efficiency and minimal environmental impact. Up to 96 per cent of raw materials used in each battery can be recovered through the company’s recycling system.