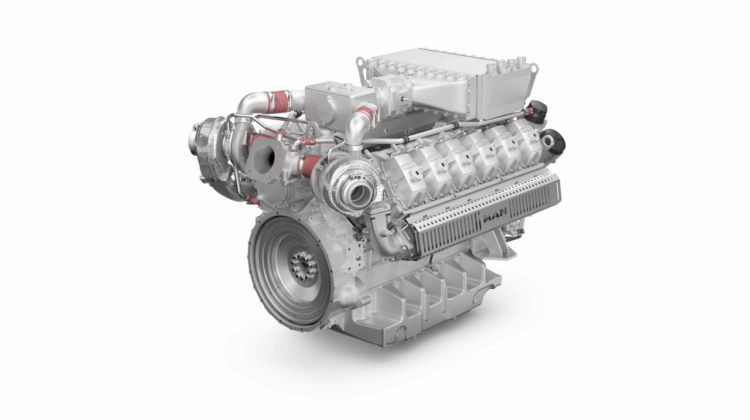

The upgraded MAN E3262 engine features a redesigned turbocharger, bronze bearings, and improved efficiency while meeting 250 mg NOx limits worldwide.

New Turbocharger Boosts MAN E32 Engine Performance

MAN Engines has upgraded its E32 gas-engine series for natural gas and biogas applications by introducing a product aimed at improving efficiency, emissions performance, and durability to meet global market requirements.

The E32 series, first launched in 2012, has more than 10,000 units installed worldwide. The latest upgrade focuses primarily on the E3262 LE202 (natural gas) and LE212 (biogas) variants, with structural changes to the turbocharger system to increase robustness.

MAN Engines said the updated turbochargers use a dry turbine housing with insulation, eliminating the need for water-bearing pipes and reducing potential leakage points, while also preventing thermal hotspots when coolant flow is insufficient. Meanwhile, new thrust and plain bearings made from a bronze alloy are designed to improve corrosion resistance and extend service life.

The new turbocharger also provides economic benefits, especially in countries where the nitrogen oxide limit is set at 250 mg/Nm³.

“The requirements of international markets were clearly the focus of the further development of our systems. Particularly in optimising efficiency, we have taken specific care to consistently take into account the globally applicable emission limits, in particular the 250 mg NOₓ. In this way, we ensure that our solutions are not only high-performance, but also globally operational,” Hubert Gossner, Head of Power & Off-Road at MAN Engines, explained.

In addition, a higher pressure reserve via the throttle valve ensures a larger power reserve. This leads to more stable engine performance, especially at increased exhaust gas back pressures or at elevated altitudes.

The modernised E3262 continues to use the long-established V12 platform underpinning the D2862 diesel engine, with a displacement of 24.2 litres in marine applications and 25.8 litres in the gas-engine configuration for stationary power and heat generation.

MAN Engines said the platform’s widespread use and field reliability make it one of the most established engines in its class. The E3262 is available in turbocharged and naturally aspirated forms and in 50 Hz and 60 Hz versions for global deployment.

The engine meets the 250 mg NOₓ/Nm³ limit without additional aftertreatment. For markets requiring 100 mg NOₓ/Nm³, it can be configured with external exhaust-gas treatment such as SCR systems to comply with the stricter standards.

The new engines can be ordered immediately, with deliveries beginning from the second half of 2026. The older LE202 and LE212 variants will still be available in the meantime.